Overview

| Video Off-site Inspection | Can provide | Warranty Period | 1 year |

| Voltage | 100-240 V | Main Material | 304 stainless steel |

| Inspection Report | Can provide | Function | Water purification |

| Core Components | Imported booster pumps, solenoid valves, EDI modules, and RO reverse osmosis membranes | Type | On the ground |

| Country of Origin | Anhui, China | Control | Electrical automatic control |

| Product Name | Industrial integrated ultrapure water system | Minimum Order Quantity | 1 unit |

| Product Color | Customizable | Core Component Warranty | 1 year |

| Operation | Automatically execute | Brand | SECCO |

| Provide After-sales Service | Drawings, videos, installation and operation and maintenance manuals, on-site services | ||

Product Specifications

| Content | Parameter |

| Ultrapure Water Production Rate (L/H) | 150 |

| Equipment Size (L×B×H) (mm) | 280×150×2000/ customizable |

| Environment Temperature (°C) | 5-45 |

| Power Supply | 100-240 V,50 Hz/60 Hz |

| Water Source Usage | Municipal tap water |

| Water Inlet Requirements | TDS<200 ppm |

| Environmental Conditions | Operating temperature (-20°C-50°C); Storage temperature (-40°C-70°C); Relative humidity <90% at 40±20°C; Atmospheric pressure (70-160) kPa |

Equipment Appearance Diagram

The industrial integrated ultrapure water system employs a four-stage process of “pretreatment + RO + EDI + polishing mixed bed” to consistently produce ultrapure water with resistivity of 18 MΩ·cm, TOC ≤ 5 ppb, and bacteria count ≤ 0.1 CFU/mL. It meets the stringent requirements of semiconductor, pharmaceutical, and other industries, featuring fully automated intelligent control and 24-hour continuous water supply.

Product Composition

The whole system is mainly composed of imported booster pumps, solenoid valves, EDI modules, and RO reverse osmosis membranes.

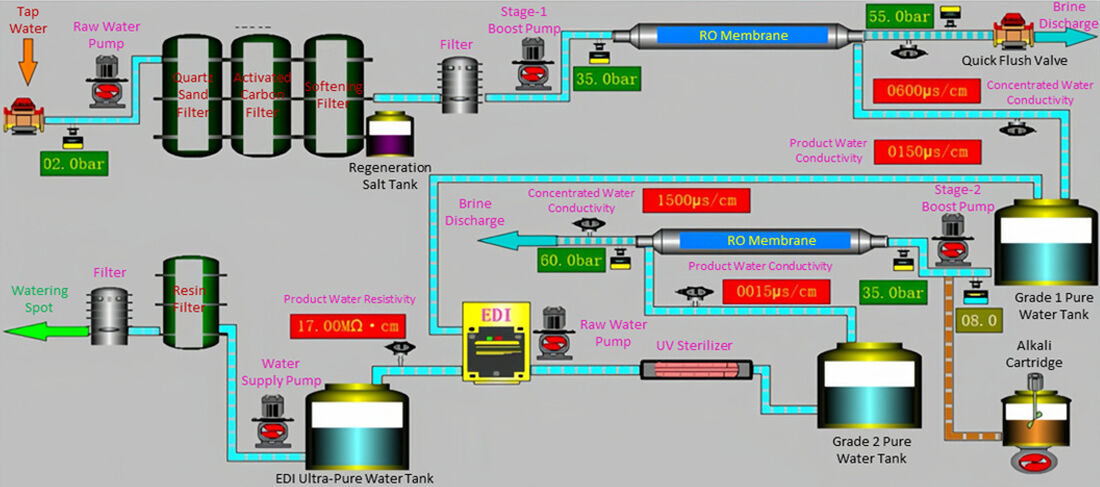

Process Flow

Technical Principle

Pretreatment + RO + EDI + Polishing mixed bed

Production Cycle

Delivery time:100 days

Support for Customization Options

| Option | Minimum Order | Customization Costs |

| Custom Colors | 1 | - |

| Custom Dimensions | 1 | - |

| Ultrapure Water Production Volume | 1 | - |

| Power Supply Power | 1 | - |

Application Scenarios

Factories, pharmaceutical facilities, hotels, schools, chemical plants, boiler systems, beverage production, precision electronics, residential communities, shopping malls.

Application Cases

A certain semiconductor enterprise has introduced a customized ultra-pure water system for its 12-inch wafer production line. The system adopts a three-stage process of "RO + EDI + Polishing mixed bed", and is equipped with 316 L stainless steel pipelines and dual-wavelength UV sterilization, stably producing ultra-pure water with a resistivity of 18 MΩ·cm (TOC ≤ 5 ppb). The system integrates an intelligent monitoring platform that can automatically adjust parameters such as water temperature (25 ± 5℃) and pressure (0.35 ± 0.02 MPa), with a maintenance cycle of up to 6 months. Operating data shows that the system operates stably for 24 hours continuously, with an annual failure rate of less than 0.2%.

Product Advantages

a. Advanced Treatment Technology: Sophisticated technology is used to ensure the production of high purity water.

b. Compact Integration: All components are well integrated in one unit, saving space and easy to manage.

c. Efficient Water Production: Capable of generating a stable supply of ultrapure water in the range of 100-1000L/h.

d. High Reliability: Stable and continuous operation with low failure rate.

e. Good Water Quality Control: Able to accurately control and regulate water quality to meet strict industrial requirements.

f. Easy Maintenance: User-friendly design for easy and cost-effective maintenance.

g. Energy Efficient: Includes energy efficient design to reduce power consumption.

h. Fast Start-up and Response: Enables quick start-up and adjustment of output to suit different production scenarios.

Minimum Order Quantity

1 unit.

After-Sales Warranty Time

One year after installation.