Industrial Wastewater Compliance Discharge System Engineering Equipment Data

Product Model: ANJ-DSS

Overview

| Video Off-site Inspection | Can provide | Treatment Capacity | 5 T/H |

| Voltage | 220V, 380V/ customizable | Warranty Period | 1 year |

| Inspection Report | Can provide | Weight | 35 T |

| Core Components | Physical-chemical, biochemical, membrane treatment components | Main Material | Carbon steel/316/Customizable |

| Country of Origin | Anhui, China | Function | Water treatment system |

| Product Name | Industrial Wastewater Compliance Discharge System Engineering | Type | On or under the ground |

| Product Color | Customizable | Control | Electrical automatic control (Siemens PLC) |

| Operation | Automatically execute | Minimum Order Quantity | 1 unit |

| Brand | SECCO | Core Component Warranty | 1 year |

| Provide After-sales Service | 24/7 response, remote guidance, and on-site engineer visit within 72 hours | ||

Product Specifications

| Content | Parameter |

| Processing Capacity (T/d) | 5 |

| Equipment Size (L×B×H) (mm) | 20000×6880×4000 |

| Weight of Equipment (T) | 35 |

| Sewage Source | Industrial wastewater |

| Craftsmanship | Physical-chemical treatment + Hydrolytic acidification + Aerobic treatment + MBR |

Equipment Appearance Diagram

Industrial wastewater compliance discharge system engineering integrating “Physical-chemical + Biological + Advanced” processes, it combines advanced oxidation equipment (rapidly decomposing refractory organic compounds), dissolved air flotation units (separating suspended impurities and oils), high-efficiency coagulation sedimentation equipment (promoting pollutant flocculation and settling), and MBR biochemical systems (microbial degradation of organic pollutants). This achieves significant removal of chemical oxygen demand (COD), ammonia nitrogen (NH3-N), total nitrogen (TN), total phosphorus (TP), and heavy metals. The system features an intelligent control module that dynamically adjusts parameters to ensure consistent compliance. Its modular design reduces costs by 30% and saves 40% space compared to traditional solutions, while providing full lifecycle services from installation to operation and maintenance.

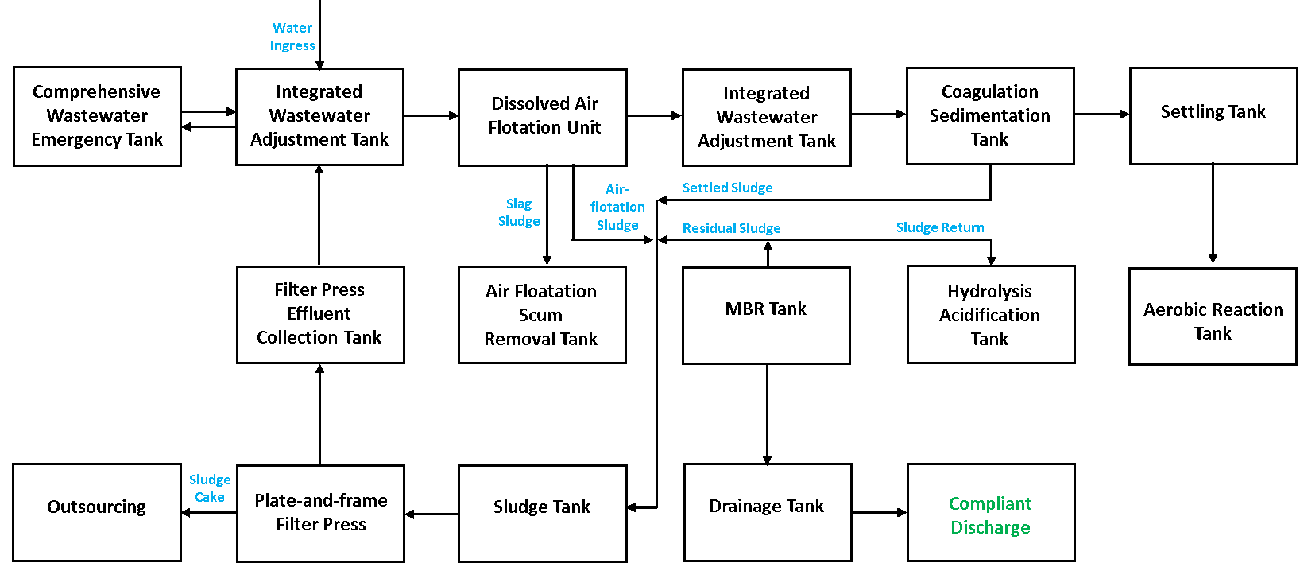

Product Composition

The whole system is mainly composed of physical-chemical, biochemical, membrane treatment.

Technical Principle

Physical-chemical + Biochemical + Deep process

Advanced oxidation equipment: Rapidly breaks down refractory organic compounds;

Dissolved air flotation unit: Separates suspended impurities and oils;

High-efficiency coagulation sedimentation equipment: Promotes coagulation and settling of pollutants;

MBR biological treatment system: Microbial degradation of organic pollutants.

Production Cycle

1 unit: 100 days

More than 1 unit: To be determined

Support for Customization Options

| Option | Minimum Order | Customization Costs |

| Custom Nameplates | 1 | - |

| Custom Colors | 1 | - |

| Custom Materials | 1 | - |

| Custom Voltage | 1 | - |

| Inlet Water Quality | 1 | - |

| Effluent Water Quality | 1 | - |

| Water Production | 1 | - |

Application Scenarios

Textile dyeing and printing industry, chemical industry, food and beverage industry, electronics industry.

Application Cases

The industrial wastewater treatment system ensures compliant discharge by comprehensively treating the following effluents: Powder coating passivation wastewater, Powder coating degreasing wastewater, Powder coating rinsing wastewater, Spray booth wastewater, Rubber workshop wastewater (including spray tower wastewater and metal part cleaning wastewater), Cooling tower circulating water.

The treated effluent meets the receiving standards for sewage treatment plants and the tertiary standards specified in the Comprehensive Wastewater Discharge Standard (GB8978-1996).

Technical Approach

Product Advantages

a. Integrated Advanced Treatment Technologies: Advanced treatment technologies are integrated to efficiently remove refractory substances and heavy metals, enhancing purification capabilities. Combined with intelligent control systems, this ensures stable compliance of effluent quality.

b. Highly Adaptable: The system adapts to multiple industries, with intelligent control dynamically adjusting parameters in real time based on water quality and flow rate. It exhibits strong shock resistance, maintaining stable compliance even with COD fluctuations of ±30%.

c. Full Lifecycle Service System: Provides end-to-end services spanning inspection, design, construction, and operation and maintenance. Expert teams offer 24/7 response with system failure rates below 0.5%. (Includes 5G remote diagnostics).

d. Modular Scalable Design: Modular equipment supports flexible capacity expansion from 50 to 5000 m³/d, reducing civil engineering costs by 40%. IoT interfaces connect directly to the operations and maintenance monitoring platform, enabling remote control and management.

Minimum Order Quantity

1 unit.

After-Sales Warranty Time

One year after installation.