Overview

The Moving Bed Biofilm Reactor (ANJ-MBBR) is a patented solution specifically developed to address challenges in rural domestic sewage treatment, including unstable treatment efficiency, high operational costs, and a shortage of qualified maintenance personnel. This innovative system adopts a sludge-film coupling method, combining activated sludge and biofilm within the same reactor. By leveraging their respective strengths while mitigating weaknesses, it demonstrates exceptional resistance to shock loads.

The ANJ-MBBR integrates core technologies including anti-filler accumulation, vortex self-stirring, intelligent control systems, and smart operation platforms. It features eco-friendly design with low investment costs, stable water quality compliance, and intelligent maintenance solutions that reduce operational expenses. Its modular and standardized series design enables rapid adaptation to diverse scenarios. The product is constructed from corrosion-resistant carbon steel, ensuring high load-bearing capacity and long service life.

This product is suitable for domestic sewage treatment scenarios such as villages, towns, residential communities, office buildings, shopping malls, schools, hospitals, and highway service stations, as well as similar small and medium-scale industrial organic wastewater treatment and reuse scenarios like slaughterhouses, aquatic product processing,and food industries. The effluent quality CODcr≤50mg/L, BOD5≤10mg/L, NH3-N≤5(8)mg/L, TN≤15mg/L, TP≤0.5mg/L, SS ≤10mg/L.

Specifications

| MBBR Series Specification | |||||

| No. | Specifications and Models | Processing Capacity(m³/d) | Equipment Size(L×B×H)(m) | Installed Power (kW) | Weight (kg) |

| 1 | MBBR-10 | 10 | 2.8×2.6×2.5 | 0.82 | 3600 |

| 2 | MBBR-20 | 20 | 3.5×3.0×2.5 | 1.58 | 4750 |

| 3 | MBBR-30 | 30 | 4.0×3.0×3.0 | 1.58 | 6500 |

| 4 | MBBR-40 | 40 | 5.0×3.0×3.0 | 3.08 | 7550 |

| 5 | MBBR-50 | 50 | 6.3×3.0×3.0 | 3.12 | 8450 |

| 6 | MBBR-100 | 100 | 9.5×3.0×3.0 | 5.62 | 11800 |

| 7 | MBBR-150 | 150 | 12.8×3.0×3.0 | 5.74 | 13800 |

| 8 | MBBR-200 | 200 | 16.5×3.0×3.0 | 5.74 | 20400 |

| 9 | >200 | The first 8 specification combinations | |||

Important Attributes (ANJ-MBBR-100 as an example)

| Video Off-site Inspection | Can provide | Processing Capacity | 100 m³/d |

| Equipment Inspection Report | Can provide | Warranty | 1 year |

| Core Components | Water pump, fan, control cabinet | Weight (KG) | 11800 |

| Country of Origin | Hefei, China | Brand | SECCO |

| Equipment Material | Q235B, custom order | Removal Rate | CODcr removal rate is more than 85%, BOD removal rate is more than 90%, ammonia nitrogen removal rate is more than 95%, total phosphorus removal rate is more than 90% |

| Filling Material | Hydrophilic modified filler | Technical Flow | Activated sludge process coupled with biofilm process |

| Product Color | Customizable | Voltage | 220V,380V, customizable |

| Control Method | Electrical automation (PLC) | Operation | Automatically execute |

| Application | Domestic sewage treatment in villages, towns, urban areas, residential communities, office buildings, shopping malls, sewage treatment in public facilities such as hospitals and schools, and wastewater treatment in small and medium-sized industries such as slaughtering, aquatic product processing and food | Provide After-sales Service | Drawings, videos, on-site services, product manuals |

| Advantages | High impact load resistance, small footprint, low energy consumption, intelligent operation | Attestation | / |

| Size (L×B×H)(m) | 9.5×3.0×3.0 | Product Name | Intelligent sewage treatment equipment-Moving Bed Biofilm Reactor |

| Installation | Above, below and semi-underground | Minimum Order Quantity | 1 set |

Packaging and shipping information (ANJ-MBBR-100 as an example)

| Sales Unit | Single item |

| Single Packing Size (L×B×H)(m) | 9.5×3.0×3.0 |

| Gross Weight of a Single Unit | 11800 |

Delivery Time

| Quantity | 1 | 2-5 | >5 |

| Eastern Time (ET) | 30 | 70 | indeterminate |

Customization Options

| Option | Minimum order | Customization costs |

| Customize the Main Material | 1 set | |

| Customize the Thickness of the Body | 1 set | |

| Customize Nameplates | 1 set | |

| Customize Logo | 1 set | |

| Customize Colors | 1 set | |

| Customize Capacity | 1 set | |

| Custom Packaging | 1 set | |

| Customized drawings | 1 set | |

| Customization | 1 set |

Application Scenarios

The ANJ-MBBR system is primarily designed for rural domestic wastewater treatment, low-temperature turbid water management, and black-odor water body remediation. It serves both new construction projects and equipment upgrades/standardization initiatives. Key applications include: wastewater treatment in villages, towns, residential complexes, office buildings, and commercial facilities; urban sewage systems; public infrastructure such as hospitals and schools; and industrial wastewater processing for small-to-medium enterprises like slaughterhouses, aquatic product processing plants, and food manufacturers.

Product Composition

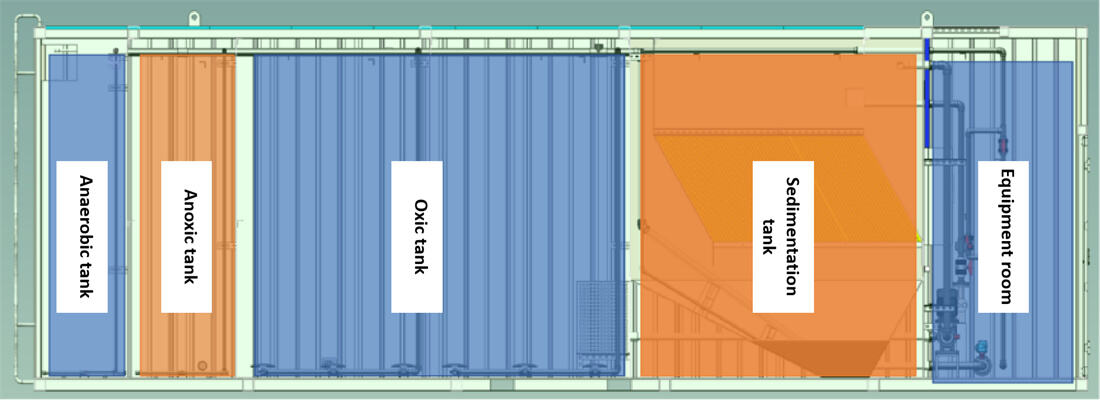

The ANJ-MBBR system mainly adopts the A/A2O process, consisting of a pre-anoxic tank, anaerobic tank, anoxic tank, oxic tank, sedimentation tank, and equipment room. The oxic tank is equipped with MBBR (Multi-membrane Blanket Reactor) media, while the sedimentation tank utilizes inclined tube or vertical flow sedimentation tanks. The re-circulation system predominantly adopts an energy-efficient air-lift return mechanism. The equipment room integrates UV disinfection units and control systems alongside standard components like fans and pumps.

Core components

| No. | Content | Specifications And Models | Quantity | Unit |

| 1 | Integrated Equipment Pool | anti-corrosion carbon steel | 1 | set |

| 2 | Electromagnetic Flow Meter | 0~15 m³/h | 1 | set |

| 3 | Content Gauge | measurement range: 0-10m | 1 | set |

| 4 | Aeration Disc | Φ215, ABS chassis | 1 | set |

| 5 | MBBR filler | 38 holes, Φ25×10mm, specific surface area>800 m2/m³ | 1 | set |

| 6 | Aeration Fan | rotary blower | 2 | set |

| 7 | Electric Ball Valve | DN50, cast iron, double flange, 220V | 1 | set |

| 8 | Electromagnetic Valve | stainless steel internal thread interface, actual working pressure 0-0.3bar, fluorine seal, 220V | 1 | set |

| 9 | UV Disinfectant | processing scale Q=10~200m³/d | 1 | set |

| 10 | Control System | control cabinet (Siemens PLC) and supporting cable and wire components | 1 | set |

Process Principle

Process Flow

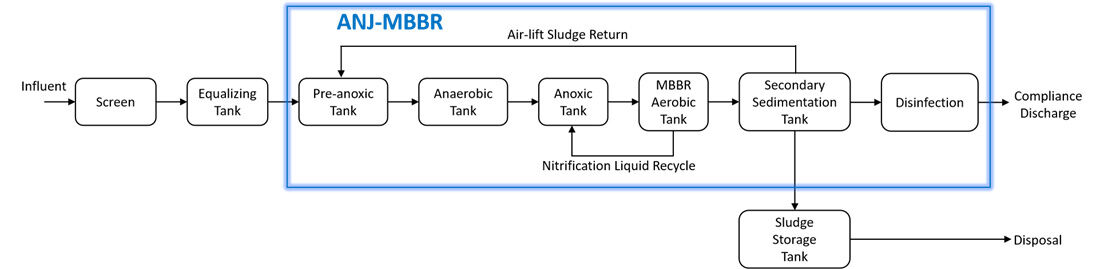

The typical process flow of ANJ-MBBR products is as follows: After intercepting large suspended solids and debris through a bar screen, wastewater enters the equalization tank for homogenization and volume adjustment. The water is then pumped to the pre-anoxic tank where it mixes with returned sludge. In this stage, nitrate and oxygen in the returned sludge are thoroughly removed, ensuring strict anaerobic conditions in the anaerobic tank. This significantly enhances the phosphorus release efficiency of phosphate accumulating bacteria within the anaerobic system.

The wastewater then enters the anaerobic tank, where phosphorus-reducing bacteria release phosphorus in a strictly anaerobic environment, preparing for subsequent aerobic phosphorus uptake. It subsequently flows into the anoxic tank, where mixed liquor recirculated from the secondary sedimentation tank contains nitrate-rich sewage. This stream can fully utilize the high-quality carbon source in the influent to achieve denitrification and nitrogen removal.

The effluent from the anoxic tank enters the MBBR aerobic tank. Under the application of high efficiency aeration and anti-filler accumulation technology, the sewage in the aerobic tank is fully contacted and mixed with the MBBR filler to effectively decompose organic matter; the phosphate accumulating bacteria absorb phosphorus in excess and realize the removal of total phosphorus through the discharge of surplus sludge.

Wastewater treated in the MBBR aerobic tank enters the secondary sedimentation tank to separate suspended sludge and impurities. The separated supernatant is channeled into the disinfection system, where harmful pathogens are eliminated before meeting discharge standards. A portion of the mixed liquor from the middle-lower section returns to the front end via recirculation, while the remaining liquid settles in the sludge hopper as excess sludge, which is then transferred to the sludge storage tank for regular external disposal.

Product Core Technology and Characteristics

Core Technical Advantages

Sludge Film Coupling Method

The core technology of ANJ-MBBR (Anaerobic Nitrification-Marine Biofilm Reactor) adopts a sludge film coupling method, where the reaction system simultaneously contains activated sludge and biofilm. This dual-process approach leverages their respective strengths while mitigating weaknesses, resulting in enhanced resistance to shock loads. Compared to traditional activated sludge process (ASP), MBBR demonstrates higher biomass production and more stable treatment performance, particularly showing greater robustness when handling water quality fluctuations.

Anti-filler Accumulation Technology

The ANJ-MBBR product utilizes proprietary anti-clogging technology (Patent: Utility Model Patent granted, an integrated sewage treatment system with anti-clogging design, ZL2022203233982). Through zoned aeration system deployment and suspended fabricated packing nets, the equipment prevents sludge accumulation. The intermittent agitation of sludge in dead zones eliminates buildup, thereby enhancing sludge loading capacity and improving wastewater treatment efficiency.

This technology not only reduces the number of failure points, but also reduces equipment investment and operation and maintenance energy consumption. By adopting the anti-fill accumulation technology, the mixing equipment inside the equipment is eliminated, which not only reduces the number of failure points, but also reduces equipment investment and operation and maintenance energy consumption.

Vortex Self-Stirring Technology

The ANJ-MBBR product achieves self-stirring of water flow within the tank through the installation of a vortex guide cylinder and hydrocyclone water distribution system (patented technology: authorized invention patent, a self-stirring wastewater treatment device and control method based on hydraulic vortex theory, ZL202311835457X). This significantly reduces energy consumption compared to traditional wastewater treatment processes while enhancing dissolved oxygen transfer efficiency and ensuring more stable treatment performance.

Compared with the traditional system that needs mechanical or gas stirring, the vortex self-stirring technology can realize the self-stirring of water flow in the tank, improve the dissolved oxygen mass transfer effect, and significantly lower the energy consumption than the traditional sewage treatment process, and the treatment effect is more stable.

Intelligent Control System

The ANJ-MBBR product, built on automated operation, utilizes big data analysis and control logic programming to activate energy-saving mode under low-load conditions (with proprietary intellectual property: Xinyu Technology's Intelligent Supervision System for Rural Wastewater Treatment, Version 1.0, 2022SR0349958). This system not only meets effluent discharge standards but also maximizes cost savings for equipment operation.

This intelligent control system can automatically adjust operation parameters according to water inflow load and water quality, optimize energy consumption, improve processing efficiency and reduce operation and maintenance costs.

Intelligent Operation And Maintenance Platform

The ANJ-MBBR product, integrated with our self-developed intelligent operation and maintenance platform (with proprietary intellectual property: Digital Intelligent Management Application Platform for Wastewater Treatment Plants V1.0, 2023SR1352648), enables true unmanned operation. This innovation addresses the persistent challenges in rural wastewater treatment facilities, including operational difficulties, high costs, frequent malfunctions, inadequate maintenance, and delayed repairs.

The Intelligent Operation And Maintenance Platform Has The Following Functions:

1) Monitor the operating status and water quality parameters in real time

2) Automatic warning and fault diagnosis

3) Remote control and parameter adjustment

4) Operation and maintenance data analysis and optimization suggestions

5) Operation and maintenance records and report generation

Product Features

(1) Green Environmental Protection Design, Low Investment And Construction Cost

Through the integrated application of a number of independent key technologies to achieve low energy consumption design, compared with similar products, the equipment cost is reduced from the source, including reducing the number of sewage pumps, omitting mechanical stirring equipment, reducing fan air volume, etc., and high efficiency and energy saving.

(2) Multiple Key Technologies Are Integrated To Ensure That The Effluent Quality Meets The Standard

By implementing the sludge film coupling process and proprietary anti-filler accumulation technology, the system demonstrates exceptional resistance to shock loads and robust capacity to handle water quality fluctuations. The integrated smart operation platform with intelligent control system enables real-time monitoring of water parameters while automatically adjusting process controls, ensuring consistent compliance with discharge standards.

(3) Digital And Intelligent Operation And Maintenance, Low Operation And Maintenance Cost

Through the application of the intelligent operation and maintenance platform and the intelligent control system, large-scale centralized operation and maintenance in the area is achieved, improving management efficiency and reducing labor costs.

(4) Modular and Series Standardized Design to Quickly Respond to Multi-scenario requirements

The compact and easy-to-maintain modular design makes the equipment more compact, facilitating installation, transportation and maintenance. At the same time, the modular design also helps improve the versatility and scalability of the equipment to meet projects of different sizes and processing needs.

A series of standardized designs are carried out, and a series of choices are more abundant to match various application scenarios with different processing scale and processing requirements.

(5) Solid and Durable, Environmentally Friendly

The product is made of carbon steel anti-corrosion material, with strong carrying capacity and long service life; no underwater electrical equipment, fewer failure points; stable and up to standard water discharge, which can be used for irrigation and reclaimed water reuse, and is environmentally friendly.

Differentiation Characteristics and Competitive Advantages

Comparison with Activated Sludge Process (ASP)

Compared with the traditional activated sludge process, ANJ-MBBR has the following advantages:

(1) Higher space efficiency: MBBR usually requires less space because of its high concentration of biomass.

(2) Stronger impact load resistance: MBBR has stronger adaptability to water quality and quantity fluctuations, and is not easy to be affected by impact load.

(3) Lower sludge yield: the amount of surplus sludge produced by MBBR system is less than that of ASP, which reduces the cost of sludge treatment.

(4) Operation and maintenance is simpler: no sludge return system is required, simplifying the operation process.

Comparison with Membrane Bioreactor (MBR)

Compared with membrane bioreactor, ANJ-MBBR has the following advantages:

(1) Lower investment cost: The initial investment of MBR is usually lower than that of MBR because expensive membrane components are not required.

(2) Lower energy consumption: The operation of MBR is usually lower than that of MBR because there is no need for membrane cleaning and suction system.

(3) Easier maintenance: MBR requires less maintenance than MBR because it does not require complex membrane maintenance procedures.

(4) Adaptability: MBBR is more likely to adapt to different types of wastewater and treatment requirements.

Comparison with Sequential Batch Reactor (SBR)

Compared with sequential batch reactor, ANJ-MBBR has the following advantages:

(1) Continuous operation: MBBR can be continuously fed and discharged, without batch operation like SBR.

(2) Higher biomass: The biofilm in MBBR provides more biomass and improves the treatment efficiency.

(3) Smaller footprint: For the same treatment capacity, MBBR usually takes up less space than SBR.

(4) Higher degree of automation: MBBR operation can be more easily automated.

Applications

Case 1: Urban Sewage Treatment Renovation Project in a Asian Country

(1) Project Background and Challenges:

a. Project location: Urban area of a country in Asia;

b. Processing scale: 400m³/d;

c. Main challenges: The project is close to the first-level protection area of Chaohu Lake, and the total nitrogen and phosphorus in the water frequently exceed the standard.

(2) ANJ-MBBR Solution:

a. Two MBBR-200 models are combined;

b. The sludge film coupling method has strong impact load resistance;

c. Equipped with intelligent operation and maintenance platform to realize remote monitoring;

d. The treatment efficiency is improved by using the filling technology and vortex self-stirring technology.

(3) Implementation Effect and Data:

a. The effluent water quality is stable to meet the local standard, and the effluent COD is less than 50mg/L, far better than the local standard.;

b. Operation and maintenance costs reduced by 40%.

Case 2: Rural Sewage Treatment Renovation Project in a Asian country

(1) Project Background and Challenges:

a. Project location: Rural sewage treatment in a country in Asia;

b. Processing scale: 10m³/d;

c. Main challenges: there are old and ineffective equipment, serious leakage, and substandard water discharge.

(2) ANJ-MBBR Solution:

a. The MBRB-10 model is adopted;

b. The film coupling process is adopted to improve the treatment efficiency;

c. The integrated intelligent control system automatically adjusts the operation parameters according to the water quality.

(3) Implementation Effect and Data:

a. The effluent COD is less than 50mg/L, far better than the local standard;

b. Ammonia nitrogen removal rate>98%;

c. The system runs stably and adapts to seasonal fluctuations;

d.The operating cost is 30% lower than the original system.

Case 3: Rural Sewage Treatment Project in a Asian Country

(1) Project Background and Challenges:

a. Project location: Rural sewage treatment in a country in Asia;

b. Processing scale: 50m³/d;

c. Main challenges: there are problems of unstable power supply, easy waterlogging in rainy season and substandard water discharge.

(2) ANJ-MBBR Solution:

a. MBBR-50 model is adopted;

b. Integrated intelligent control system, adapt to power fluctuations;

c. Equipped with intelligent operation and maintenance platform to realize remote monitoring;

d. The integrated intelligent control system automatically adjusts the operation parameters according to the water quality.

(3) Implementation Effect and Data:

a. The effluent COD is less than 50mg/L, far better than the local standard;

b. Ammonia nitrogen removal rate>98%;

c. The system runs stably and adapts to seasonal fluctuations;

d. The operating cost is 30% lower than the original system.