Overview

| Video off the factory and check | Can provide | Handling capacity | 10/20/50(T/H) |

| Mechanical test report | Can provide | Defects liability period | 1 year |

| Core components | High concentration system, evaporation crystallization technology | Colour | Customizable |

| Country of origin | Anhui, China | Main material | Carbon steel/stainless steel |

| Product name | Waste water zero discharge system engineering | Function | Waste water recycling |

| Operate | Automatically execute | Control | Electrical automatic control (Siemens PLC) |

| Brand | SECCO | Minimum order quantity | 1 unit |

| Core component warranty | 1 year | Application scenarios | Industrial effluent |

| Provide after-sales service | Drawings, videos, installation and operation and maintenance manuals, on-site services | ||

Product Specifications

| Product name | Model | Trade | Product | Material quality | Technology |

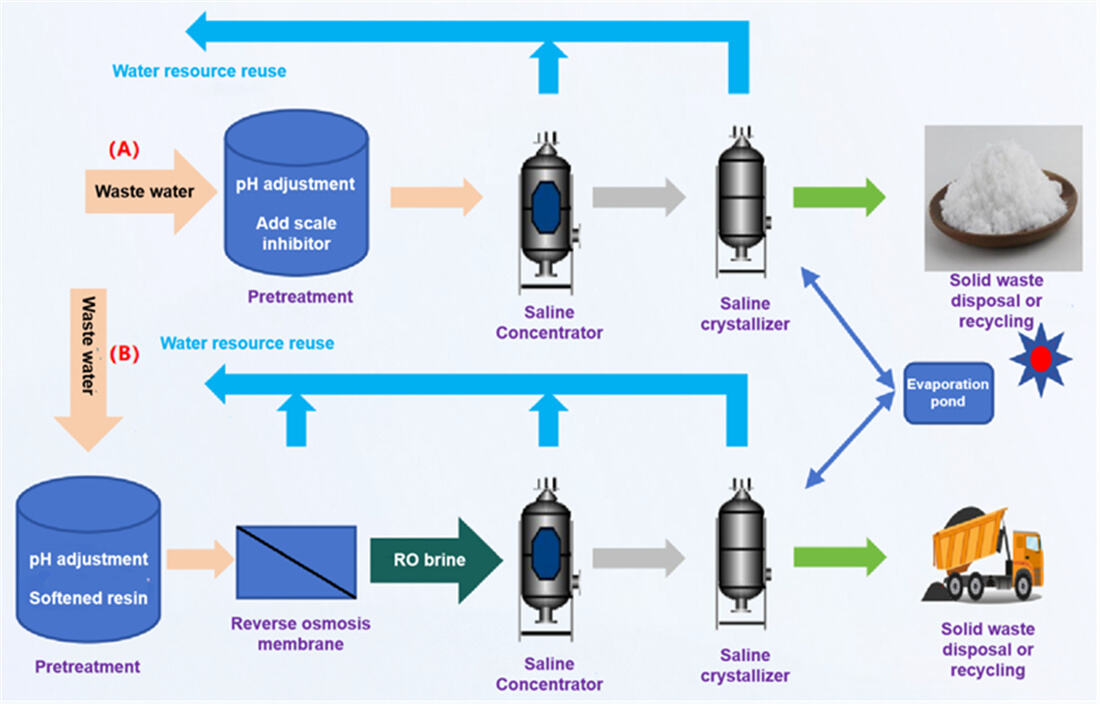

| Waste water zero discharge system engineering | ANJ-ZLD-10 | Coking wastewater | The product water meets the reuse standard, and the product salt meets the industrial standard | Carbon steel/stainless steel | Pre-treatment + membrane concentration + evaporation crystallization |

| ANJ-ZLD-20 | Electronic industry wastewater | Product water 100% reuse | Carbon steel/stainless steel | Ultrafiltration + reverse osmosis + DTRO + evaporation crystallization | |

| ANJ-ZLD-25 | Power plant desulfurization wastewater | The product water meets the reuse standard, and the product salt meets the industrial standard | Carbon steel/stainless steel | Pre-treatment + nanofiltration salt separation + evaporation crystallization | |

| ANJ-ZLD-50 | Electrophoretic wastewater | Product water 100% reuse | Carbon steel/stainless steel | Pre-treatment + membrane concentration + low temperature evaporation |

Equipment Appearance Diagram

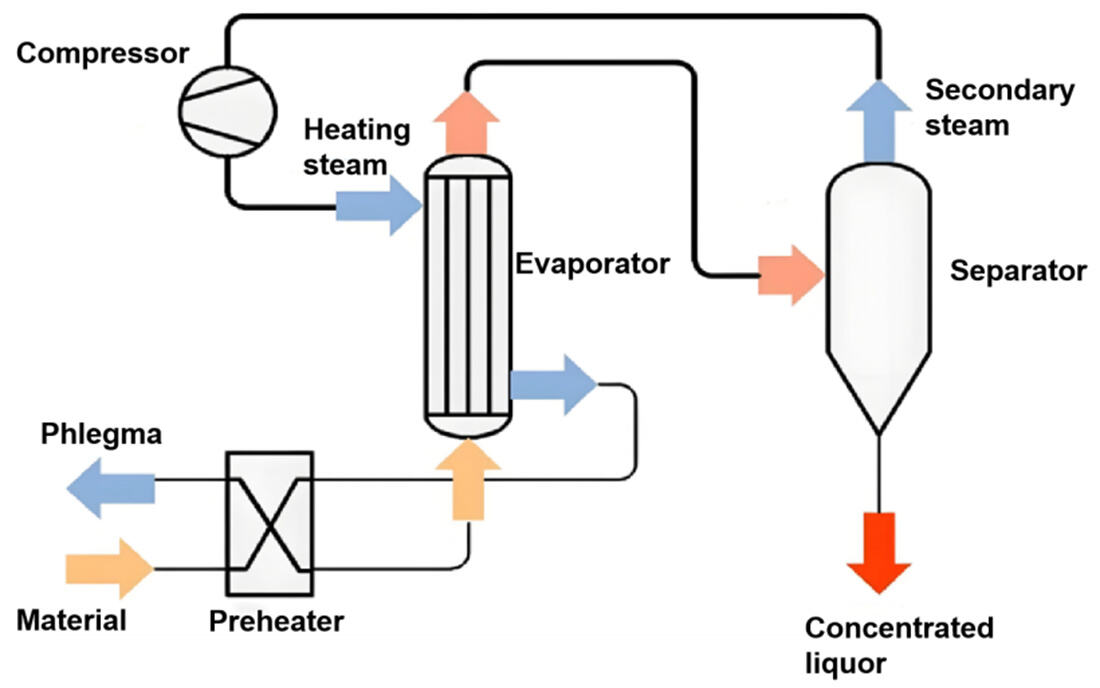

RO, STRO, DTRO reverse osmosis and MVR evaporation technology are integrated to achieve simultaneous removal of COD, salt and heavy metals, and water reuse rate is more than 98%.

Production Cycle

| Number (plants) | 1 | >1 |

| Time (days) | 150 | To be determined |

Support for Customization Options

| Option | Minimum order quantity | Customization costs |

| Nameplate and brand name | ||

| Brushing or polishing | 1 | |

| Water intake quality | ||

| Customized | 1 | |

| Water quality | ||

| Local Standards | 1 | |

| Water treatment | ||

| 10T/H | 1 | |

| 50T/H | 1 | |

| 100T/H | 1 | |

| Customized | 1 | |

| Processing techniques | ||

| Customized | 1 | |

| Power supply | ||

| Customized | 1 | |

| Type of power supply | ||

| Customized | 1 |

Packaging Dimensions

| Product name | Model | Trade | Technology | Equipment size (m) (L × B×H) | Weight(T) | Minimum order quantity |

| Waste water zero discharge system engineering | ANJ-ZLD-10 | Coking wastewater | Pre-treatment + membrane concentration + evaporation crystallization | 30×3×3 | 30 | 1 |

| ANJ-ZLD-20 | Electronic industry wastewater | Ultrafiltration + reverse osmosis + DTRO + evaporation crystallization | 50×3×3 | 40 | 1 | |

| ANJ-ZLD-25 | Power plant desulfurization wastewater | Pre-treatment + nanofiltration salt separation + evaporation crystallization | 50×3×3 | 40 | 1 | |

| ANJ-ZLD-50 | Electrophoretic wastewater | Pre-treatment + membrane concentration + low temperature evaporation | 30×3×3 | 30 | 1 |

Application Scenarios

-

Petrochemical industry

Zero discharge of high salt, high organic matter and high toxicity wastewater produced in the production process.

-

Electroplating industry

Treatment of heavy metal and acid and alkali wastewater in electroplating wastewater, recovery of heavy metal resources.

-

Mining industry

The heavy metal and high salt wastewater produced in the process of mining and mineral processing is treated.

Application Cases

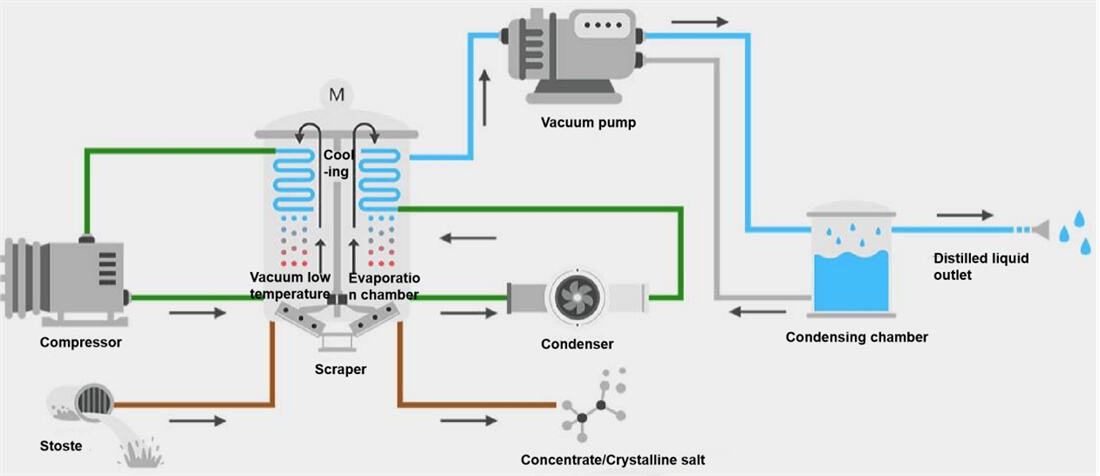

a. The wastewater from coal chemical industry is evaporated and crystallized by MVR, and the condensed water is reused to the production line to form resource recycling.

b. In a zero discharge project of coking wastewater, the salt content of sodium chloride product is 97.5%, and that of sodium sulfate product is>98%.

Product Advantages

a. Thorough treatment of contaminants

All pollutants in the wastewater are separated, transformed and solidified to achieve zero discharge of wastewater.

b. Intelligent control configuration

The advanced automatic control system can realize remote monitoring and operation, and monitor the operating status of the system in real time.

c. Resource recovery

It can recycle the useful substances in wastewater, such as heavy metals and salts, so as to realize the recycling of resources and reduce the cost of enterprises.

d. High integration

Modular design, high integration and small footprint.

Standardized and customized services

We pursue excellence in intelligent manufacturing through digital transformation and automation upgrades. By actively expanding the application of big data analytics and artificial intelligence technologies, we dedicate ourselves to smart manufacturing to deliver outstanding products and services. Our offerings include a range of rigorously tested, high-performance standardized products tailored for diverse industry needs. We also provide customized solutions, with our professional design team creating tailored solutions to meet unique requirements. Through comprehensive services, we craft premium mechanical products and system solutions with meticulous craftsmanship.

Minimum order quantity

1 unit.

After-sales warranty time

One year after installation.