Overview

The Negative Pressure Anoxic/Oxic Biofilter (ANJ-FBAF) is a wastewater treatment system specifically designed for rural areas with low pollutant concentrations and irregular discharge patterns, while meeting the low-consumption operation requirements of sewage facilities. This integrated solution combines biological oxidation with suspended solids retention through biofilm technology. Its innovative design creates a controlled anoxic-oxic environment within the unit, ensuring stable compliance with effluent quality standards.

With a single-unit capacity ranging from 5 to 50 tons per day and a maximum installed power of 300W, the system offers compact footprint, cost efficiency, standardized engineering, intelligent operation, energy savings, low noise levels, and odor-free performance. Ideal for small-scale domestic wastewater treatment and low-concentration organic wastewater management in scattered rural settlements, villas, guesthouses, agritourism facilities, schools, and medical rehabilitation zones.

Specifications and Models

| No. | Specifications and Models | Handling Capacity(m³/d) | Equipment Size(L×B×H)(m) | Installed Power(W) | Weight of Equipment (Kg) | Filter Weight (Kg) | Total Weight (Kg) |

| 1 | FBAF-5 | 5 | 1.0×1.0×3.0 | The temperature difference between the inside and outside of the equipment is more than 4℃, 50W; the temperature difference between the inside and outside of the equipment is less than or equal to 4℃, 300W | 1150 | 450 | 1600 |

| 2 | FBAF-10 | 10 | 1.5×1.0×3.0 | 1850 | 850 | 2700 | |

| 3 | FBAF-15 | 15 | 2.0×1.5×3.0 | 2300 | 1700 | 4000 | |

| 4 | FBAF-20 | 20 | 2300 | 1700 | 4000 | ||

| 5 | FBAF-25 | 25 | 2300 | 1700 | 4000 | ||

| 6 | FBAF-30 | 30 | 2.0×1.8×3.0 | 2700 | 2600 | 5300 | |

| 7 | FBAF-35 | 35 | 2700 | 2600 | 5300 | ||

| 8 | FBAF-40 | 40 | 2.5×1.8×3.0 | The temperature difference between the inside and outside of the equipment is more than 4℃, 80W; the temperature difference between the inside and outside of the equipment is less than or equal to 4℃, 300W | 3200 | 4100 | 7300 |

| 9 | FBAF-45 | 45 | 3200 | 4100 | 7300 | ||

| 10 | FBAF-50 | 50 | 3200 | 4100 | 7300 | ||

| 11 | / | >50 | The first ten specifications | ||||

Important Attributes (using ANJ-FBAF-10 as an example)

| Video Off-Site Inspection | Can provide | Handling Capacity | 10 m³/d |

| Equipment Inspection Report | Can provide | Defects Liability Period | 1 year |

| Core Components | Water distribution system, modular biological filler, gas distribution system, control cabinet | Weight (Kg) | Equipment weight: 1850Filter material weight: 850Total weight: 2700 |

| Country of Origin | Hefei, China | Brand | SECCO |

| Equipment Material | Q235B, custom order | Removal Rate | CODcr:70~85%;SS:80~95%;NH4+-N:75~80% |

| Filling Material | Bio-ceramic filter material | Technical Flow | Biological contact oxidation, suspended matter adsorption and interception |

| Color | Custom made | Voltage | 220V,380V, custom |

| Control Method | Electrical automation (PLC) | Operation | Automatically execute |

| Application Scenarios | Treatment of domestic sewage from decentralized rural areas, villas, inns, farmhouse restaurants, schools, hospital sanatoriums, etc., as well as low-concentration organic wastewater generated by washing processes or after pretreatment from soybean products workshops, textile printing and dyeing, food and beverage, livestock and poultry breeding. | Provide After-Sales Service | Drawings, videos, on-site services, product manuals |

| Advantages | Save floor space, low investment cost, standardized design, intelligent operation, low energy consumption, low noise, no odor | Attestation | / |

| Size (L×B×H)(m) | 1.5×1.0×3.0 | Product Name | Intelligent sewage treatment equipment-Negative Pressure Anoxic/Oxic Biofilter |

| Installation | Overground | Minimum Order Quantity | 1 set |

Packaging and Shipping Information (using ANJ-FBAF-10 as an example)

| Sales Unit | Single item |

| Single Package Size (L×B×Hm) | 1.5×1.0×3.0 |

| Gross Weight Of a Single Product | Equipment weight: 1850kgFilter material weight: 850kgTotal weight: 2700kg |

Delivery Time

| Quantity | 1 | 2-5 | >5 |

| Eastern Time (Et) | 30 | 70 | indeterminate |

Custom Options

| Option | Minimum Order | Customization Costs |

| Customize The Main Material | 1 set | |

| Customize The Thickness Of The Body | 1 set | |

| Custom Nameplates | 1 set | |

| Custom Made Logo | 1 set | |

| Custom Colors | 1 set | |

| Customization Capacity | 1 set | |

| Custom Packaging | 1 set | |

| Map Customization | 1 set | |

| Customized | 1 set |

Application Scenarios

Treatment of domestic sewage from decentralized rural areas, villas, inns, farmhouse restaurants, schools, hospital sanatoriums, etc., as well as low-concentration organic wastewater generated by washing processes or after pretreatment from soybean products workshops, textile printing and dyeing, food and beverage, livestock and poultry breeding.

Product Structure

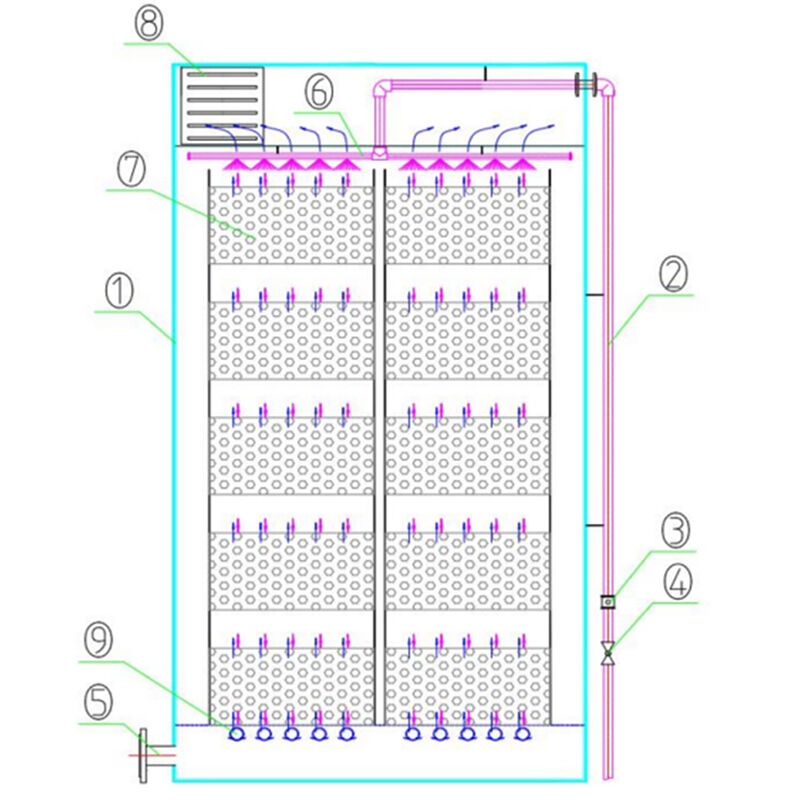

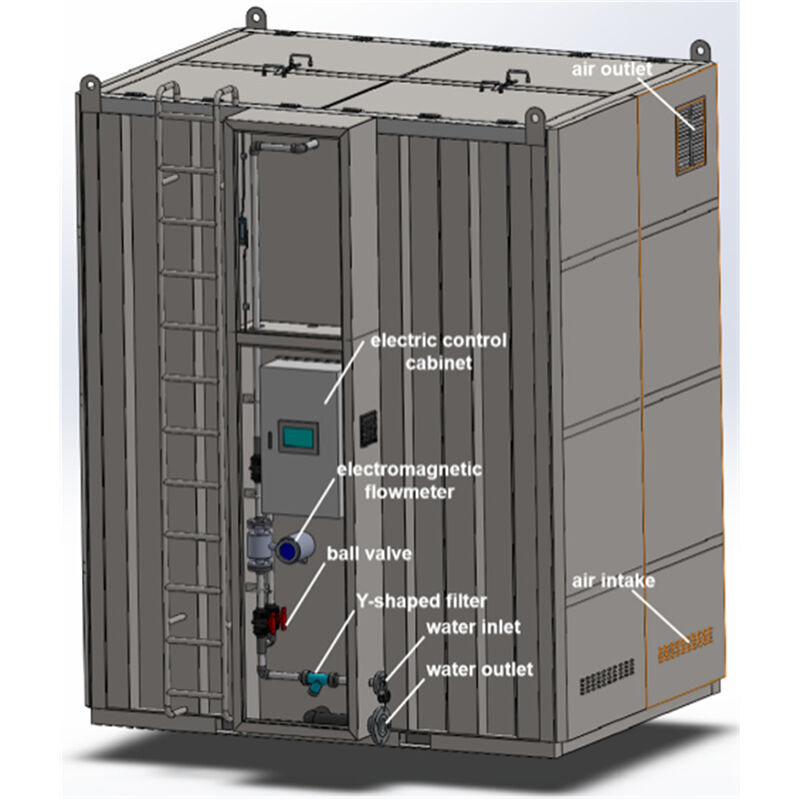

The ANJ-FBAF product is an enhanced biological filter system utilizing the biofilm process. Unlike conventional models, it features innovative optimizations in critical components such as filter media and gas distribution. This integrated solution combines a water distribution system, modular biological media, and gas delivery mechanisms to deliver a complete environmental treatment system.

Figure: ① Equipment Body, ② Inlet Pipe, ③ Flow Meter, ④ Valve, ⑤ Outlet Pipe, ⑥ Water Distribution Assembly, ⑦ Module Biological Filler, ⑧ Exhaust Fan, ⑨ Ventilation Port.

Core Component List

| No. | Name | Detailed Information Or Components | Quantity | Unit |

| 1 | Equipment subject | Carbon steel anticorrosion | 1 | Suite |

| 2 | Inflow component | Pipe fittings, Y-type filters, flange joints, etc | 1 | Suite |

| 3 | Water filling components | Including spiral nozzle, square water distribution pipeline, ball valve, etc. | 1 | Suite |

| 4 | Module biological filler | Including filter frame, ceramic biofilter material | 1 | Suite |

| 5 | Gas distribution system | Including ventilation fan, ventilation port, wind plate, etc. | 1 | Suite |

| 6 | Electromagnetic flowmeter | Flange, DC24V/AC220V | 1 | Set |

| 7 | Water output component | Pipes and fittings, flange joints | ||

| 8 | Control cabinet | Including electrical automatic control (PLC) | 1 | Suite |

Principle And Process Flow

Operational Principle

The wastewater is evenly distributed onto the packing material through a water distribution system at the top of the equipment. In an oxic environment, microorganisms decompose organic matter in the water, purifying the sewage while multiplying and forming a biofilm on the packing surface. When the biofilm reaches a certain thickness, oxygen diffusion into its interior becomes restricted.

The outer layer remains aerobic while the inner layer becomes hypoxic or even anaerobic, eventually causing the biofilm to detach and achieving nitrogen and phosphorus removal. Meanwhile, by arranging modular biological packing in specific patterns and coordinating with the aeration system, the equipment creates distinct oxic-anoxic microenvironments from bottom to top and from outside to inside. This effectively enhances nitrification and denitrification bacteria activity, improving nitrogen removal efficiency. Suspended solids in the wastewater are significantly reduced through the packing's filtration. Ultimately, the treated wastewater meets discharge standards after undergoing biological processes and packing filtration at the equipment's base.

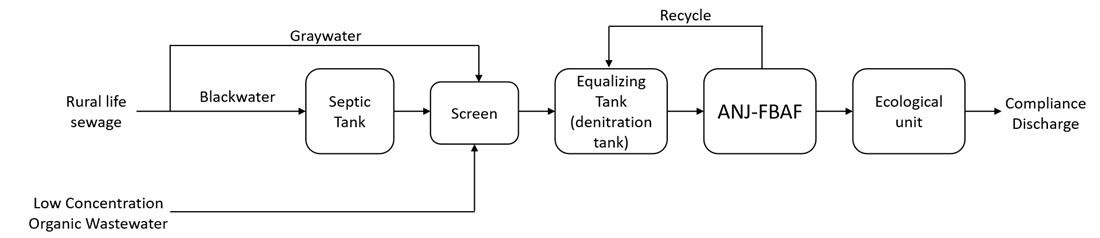

Product Recommendation Process

Recommended Process Flow for This Product: Rural domestic sewage treated with black water/black ash water from septic tanks, gray water from black ash separation, or low-concentration organic wastewater enters the sewage treatment system. First, large suspended solids and debris are intercepted by a screen before entering the equalization tank for homogenization and volume adjustment. The wastewater is then pumped to the top distribution system of the ANJ-FBAF module, where it is evenly distributed onto the biological filler. Under microbial action, organic matter and ammonia nitrogen are efficiently removed.

Through bottom-up flow and lateral movement of biological fillers, varying degrees of anoxic-oxic microenvironments are formed for nitrogen and phosphorus removal, while suspended solids are intercepted by the fillers. When high total nitrogen removal is required, a return flow from the ANJ-FBAF to the denitrification tank (equalization tank) allows nitrate nitrogen to enter the anoxic environment and be reduced to nitrogen gas via denitrifying bacteria. For higher total phosphorus removal needs, an ecological treatment unit is added after the ANJ-FBAF to purify phosphorus through vegetation. Finally, the effluent meets discharge standards.

Product Core Technology And Characteristics

Core Technology

Modular Biological Filler System

The self-developed modular biological filler is not merely a simple stack, but a scientifically designed and systematically arranged structure. This configuration significantly increases the specific surface area, providing vast space for microbial attachment and proliferation. It forms a high-density, highly active biofilm, which serves as the foundation for efficient removal of organic matter (COD/BOD) and ammonia nitrogen (NH3-N).

The specific arrangement of filler actively creates a "from outside to inside" dissolved oxygen gradient, which is the key to realize simultaneous nitrification and denitrification (SND) nitrogen removal.

Multi-Stage Gas Distribution And Microenvironment Construction Technology

The gas distribution system is innovatively optimized to work with the module filler to precisely control the distribution of oxygen inside the equipment.

The system not only achieves top-down regulation of overall oxygen concentration but, more crucially, creates countless "aerobic-deoxygenative-anoxic" microenvironments at the microscopic level through synergistic interaction with the packing material. This enables simultaneous and efficient co-location of nitrification (oxic) and denitrification (anoxic) reactions within a single spatial domain, significantly enhancing nitrogen removal efficiency while reducing dependence on external carbon sources and complex recirculation systems.

Simultaneous Nitrification And Denitrification (SND) Nitrogen Removal Mechanism

While traditional processes require sewage to be pumped back and forth between oxic and anoxic tanks to complete the nitrogen removal process, ANJ-FBAF uses its unique packing and gas distribution system to achieve this complex process in a single reactor.

This mechanism not only simplifies the process and reduces energy consumption, but also improves treatment efficiency and cost-effectiveness by utilizing carbon sources in raw water for denitrification.

Product Features

(1) Strong impact load: the biological filler of this product module is attached with a large number of biofilm, which is not as sensitive to the change of organic load and hydraulic load as the traditional activated sludge, and there is no sludge bulking problem, and the treatment efficiency is high.

(2) Small footprint: This product has a large height-to-diameter ratio, and the contact time between sewage and biofilm is more sufficient. Under the premise of ensuring good treatment effect, the footprint is small.

(3) Low investment cost: the product structure is simple, the materials used are economical and easy to obtain, there is no strict requirement on the use environment, the overall investment cost is low.

(4) Low operating cost: the power equipment of this product only has two low-consumption exhaust fans, and the total installed power is only 300W at most, so the operating energy consumption is low.

(5) Intelligent operation: This product is equipped with intelligent control system, fully automatic operation, and unattended.

(6) Solid and durable: the product shell is made of steel structure for anti-corrosion, with long service life, strong bearing capacity, good sealing, and easy to deform.

(7) Environmentally friendly: The system adopts a closed structure to isolate the impact of noise, sewage and odor on the external environment, with low noise and no odor. The effluent can be used for irrigation and water reuse.

(8) Easy to install: the product adopts integrated design, and the appearance size series is easy to standardize design and installation.

(9) Quality assurance: The products have independent intellectual property rights of the enterprise, formulate enterprise standards, and pass third-party testing.

Differentiation Characteristics And Market Competitive Advantages

Table 5-1 Comparison Of Similar Products

| Compare Items | Distributed FBAF Smart Device | Baf Aeration Biofilter | Taf Non-Clogging Aeration Biofilter | Tower Biological Filter |

| Main Process | Biological membrane method, combined with intelligent control system | Biological membrane method, aeration biofilter | Improved biofilm method, T-type filter brick | Biological membrane method, vertical flow filter |

| Filter Type | Modular regular packing | Granular filter material (such as clay ball, activated carbon) | T-type filter brick | Clay, volcanic rock, etc |

| Cod Removal Rate | 70%-85% | 70%-85% | 80%-90% | 70%-85% |

| Ammonia Nitrogen Removal Rate | 75%-80% | 75%-85% | 85%-90% | 80%-90% |

| SS Removal Rate | 80%-95% | 75%-85% | 80%-90% | 75%-85% |

| Impact Load Resistance | Strong, adapt to water quality fluctuations | Medium, the water quality should be controlled | Strong, not easy to clog | Strong, suitable for high load operation |

| Anti-Block Ability | Strong, blocking warning | Medium, frequent backwash | Strong, not easy to clog | Weak, easy to clog |

| Installed Power | The installed power is less than 300W | Installed power is greater than or equal to 0.75kW | Installed power is greater than or equal to 0.75kW | 0 |

| Applicable Scene | Decentralized sewage treatment, such as rural and small communities | Municipal sewage, industrial sewage | Municipal sewage, industrial sewage | Decentralized sewage treatment |

| Equipment Features | Integrated design, high degree of automation | The traditional biofilter runs stably | No blockage design, low maintenance cost | Compact structure, suitable for high load operation |

| Investment And Operation Costs | Low initial investment and low operation and maintenance costs | High initial investment and high operation and maintenance costs | The initial investment is high and the operation and maintenance cost is medium | The initial investment is moderate and the operation and maintenance cost is low |

Applications

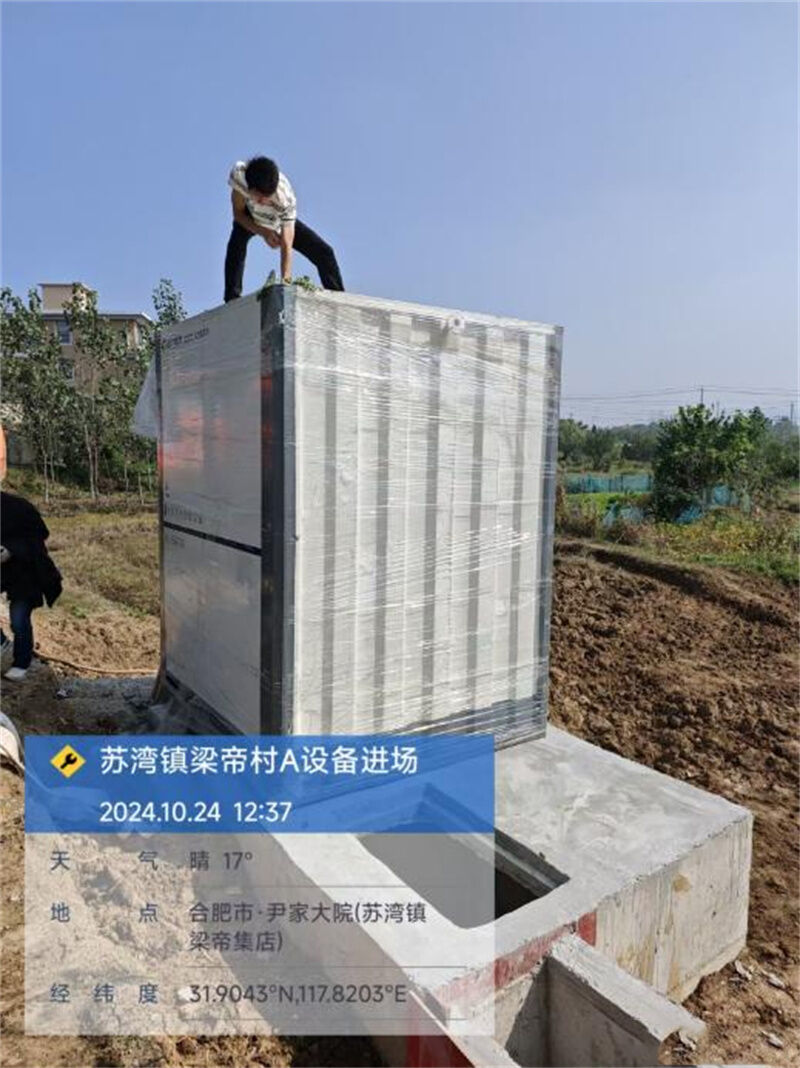

Project 1: Rural Sewage Treatment In Hefei, Anhui Province, China

Project location: Chaohu City, Hefei City, Anhui Province, China

Equipment used: ANJ-FBAF-30

Processing scale: 30 m³/d

Main process: Negative Pressure Anoxic/Oxic Biofilter (ANJ-FBAF)

Installation environment: around farmland

Effluent quality: CODCr ≤ 60 mg/L, SS ≤ 30 mg/L, and NH4+-N ≤ 15 (25) mg/L. (The values outside parentheses represent control indicators for water temperatures>12℃, while those inside parentheses apply when water temperature is ≤12℃.)

Project effect: rural domestic sewage is effectively collected, the effluent is stable and up to standard, and the rural water environment is significantly improved.

Figure: Project photos (top: transportation; left: in place; right: normal operation of the station)

Project 2: Rural sewage treatment in Hefei, Anhui Province, China

Project location: Chaohu City, Hefei City, Anhui Province, China

Equipment used: ANJ-FBAF-30

Processing scale: 30 m³/d

Main process: Negative Pressure Anoxic/Oxic Biofilter (ANJ-FBAF)

Installation environment: village edge

Effluent quality: CODCr ≤60 mg/L, SS ≤30 mg/L, and NH4+-N ≤15 (25) mg/L. (Values outside parentheses represent control criteria for water temperatures>12℃, while those within parentheses apply when water temperature ≤12℃)

Project effect: rural domestic sewage is effectively collected, the effluent is stable and up to standard, and the rural water environment is significantly improved.

Project site photos (top: transportation and lifting; bottom: equipment in place)

Project 3: Rural sewage treatment in Hefei, Anhui Province, China

Project location: Hefei, Anhui Province, China

Equipment used: ANJ-FBAF-30

Processing scale: 30 m³/d

Main process: Negative Pressure Anoxic/Oxic Biofilter (ANJ-FBAF)

Installation environment: farmers market

Effluent quality: CODCr ≤ 60 mg/L, SS ≤ 30 mg/L, and NH4+-N ≤ 15 (25) mg/L. (The values outside parentheses represent control indicators for water temperatures>12℃, while those inside parentheses apply when water temperature ≤12℃)

Project effect: rural domestic sewage is effectively collected, the effluent is stable and up to standard, and the rural water environment is significantly improved.

Project site photos (top: transportation and lifting; bottom: equipment in place)

Please provide your project data so that we can design a more suitable equipment for you.

| Parameter | Inflow water quality (mg/L) (ppm) | Water quality (mg/L) (ppm) |

| CODcr | ||

| BOD5 | ||

| TSS | ||

| NH4+-N | ||

| TN | ||

| TP | ||

| pH | ||

| Colibacillus | ||

| Other | ||

| Handling Capacity | m3/d | |

| Whether To Assemble In The Control Room | ||

| Appearance Requirements | For details of the minimalist look, please refer to our brochure. | |

| Voltage, Frequency, Phase | ||

| Distance Between Regulator And Equipment | ||

| Flange Interface Specifications | ||

| Special Requirements | ||