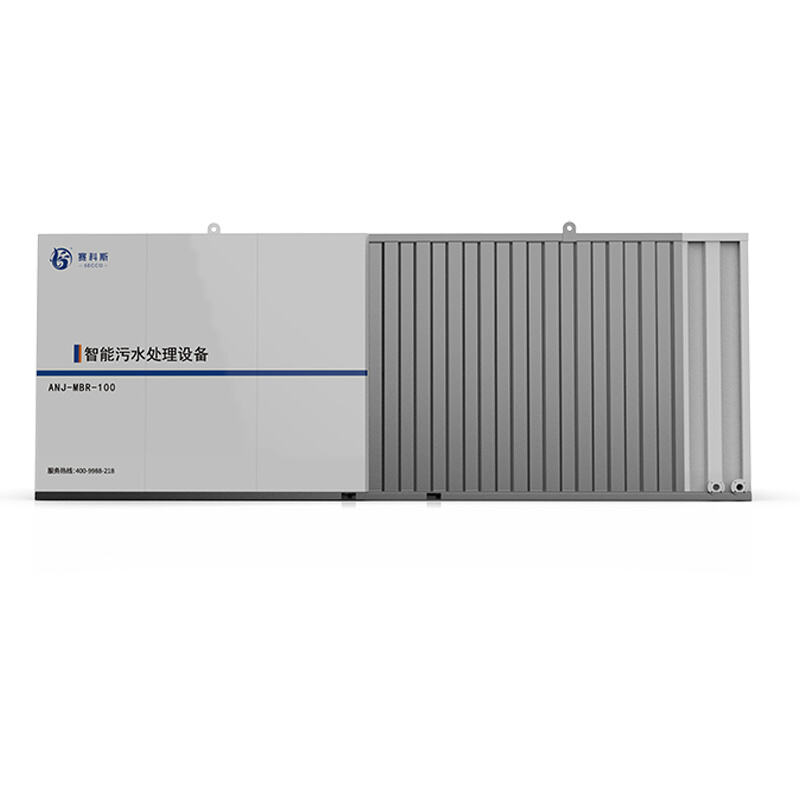

Overview

The ANJ-MBR is an intelligent wastewater treatment system developed to address challenges in traditional integrated sewage treatment equipment, such as high membrane fouling and operational difficulties. This innovative device combines activated sludge process and biofilm technology, featuring a highly integrated approach. It integrates biological denitrification, phosphorus removal, and membrane separation technologies.

Utilizing nano-material-modified flat membranes with long service life and strong anti-fouling capabilities, the system achieves simultaneous removal of organic matter and nitrogen/phosphorus pollutants. The membrane elements demonstrate enhanced fouling resistance, reduced cleaning frequency, extended service life, and minimized flux reduction rate. Through optimized process design, the system ensures stable compliance with effluent quality standards, achieving CODcr≤30mg/L, NH3-N≤5mg/L, TN≤15mg/L, TP≤0.5mg/L, SS ≤10 mg/L. Key features include superior water quality, broad applicability, extended membrane fouling intervals, and high automation levels.

Specifications

Specifications And Models

| No. | Specifications and models | Handling capacity (m³/d) | Size of device(L×B×H)(m) | Installed power (W) | Weight of equipment (KG) |

| 1 | ANJ-MBR-100 | 100 | 8×3×3 | 9205 | 8600 |

| 2 | / | Accept customization | |||

Important Attributes

| Video off-site inspection | Can provide | Handling capacity | 100m3/d or custom |

| Equipment inspection report | Can provide | Defects liability period | 1 year |

| Installed power | 9205W | Weight (KG) | 8600 |

| Place of production | Anhui, China | Brand | SECCO |

| Material of equipment | Carbon steel corrosion or fiberglass, accept customization | Removal rate | CODcr removal rate 80%~90%;NH4+-N removal rate 75%~90%;TP removal rate 80%~95%;SS removal rate 95%~98%; |

| Voltage | 220V/380V/ customizable | Process flow | A-AAO+MBR |

| Pigment | Custom made | Core components | Water pump, fan, MBR system, electrical control cabinet, instrument |

| Control method | Electrical automation (PLC) | Operate | Automatically execute |

| Size (L×B×H) (m) | 8×3×3 | Superiority | It covers a small area, has excellent and stable water quality, standardized design and intelligent operation |

| Product name | Intelligent sewage treatment equipment-low frequency cleaning membrane bioreactor | Attestation | / |

| Way to install | Above or below ground | Minimum order quantity | 1 set |

| Provide after-sales service | Drawings, videos, on-site services, product manuals | Application scenarios | Centralized sewage treatment plants, water source protection areas, scenic spots, homestay catering, food processing and other scenarios with strict effluent quality requirements or high influent concentration can be used as both advanced treatment equipment for domestic sewage and supporting treatment units for industrial wastewater. |

Packaging And Shipping Information

| Marketing unit | Single item |

| Single package size (L×B×H) (m) | 8×3×3 |

| Gross weight of individual product | 8600kg |

Delivery Time

| Quantity | 1 | 2-5 | >5 |

| Eastern Time (ET) | 30 | 70 | Indeterminate |

Customization Options

| Option | Minimum order | Customization costs |

| Customize main material | 1 set | |

| Customized body thickness | 1 set | |

| Custom nameplates | 1 set | |

| Custom made logo | 1 set | |

| Customise your colour | 1 set | |

| Customization processing capacity | 1 set | |

| Custom packaging | 1 set | |

| Mapping customization | 1 set | |

| Customization | 1 set |

Application Scenarios

It is mainly used in centralized sewage treatment plants, water source protection areas, scenic spots, homestay catering, food processing and other scenarios with strict effluent water quality requirements or high influent concentration. It can be used as a deep treatment equipment for domestic sewage or as a supporting treatment unit for industrial wastewater.

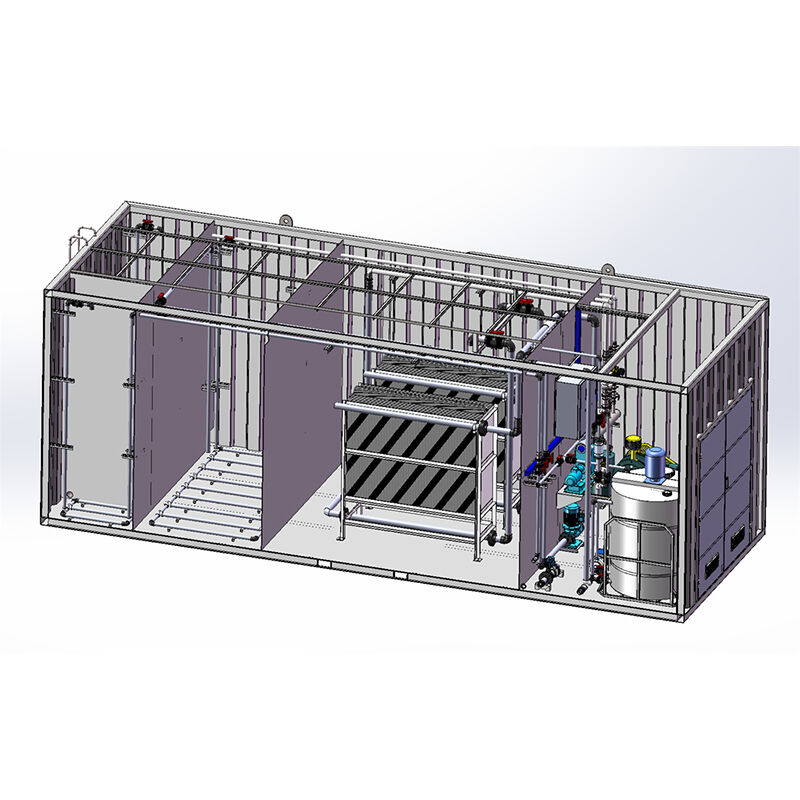

Product Composition

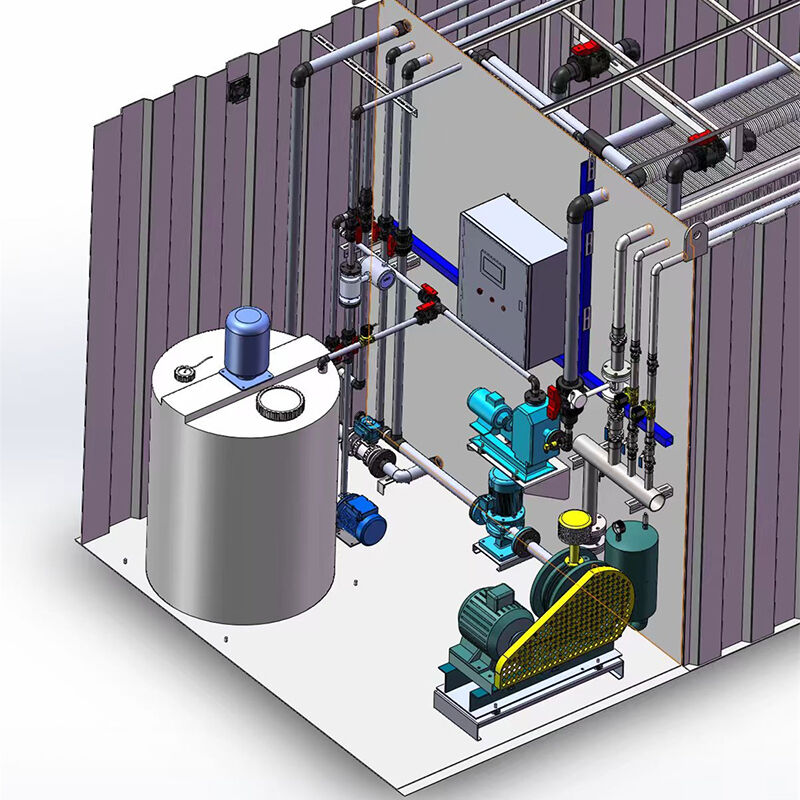

The whole system is mainly composed of membrane components, blower, production water pump, sludge pump, cleaning system, instrumentation and automation electrical system.

List Of Core Components

| Name | Model parameters | Quantity | Unit |

| Equipment pool | Carbon steel anticorrosion | 1 | set |

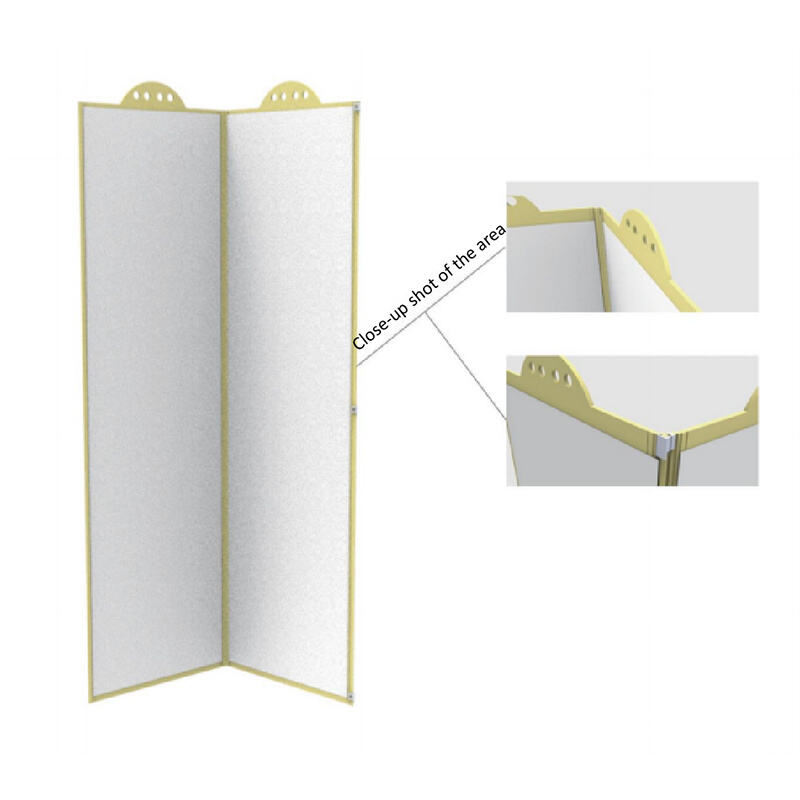

| MBR membrane system | Flat membrane, membrane pore size 0.1μm, average membrane flux 18L/ (㎡`h) | 2 | suite |

| Production pumps | Self-priming pump | 1 | set |

| Membrane chemical cleaning system | Sodium hypochlorite filling tank, with filling pump, level gauge and so on | 1 | suite |

| Fan | Rotary blower | 1 | set |

| Reflux pump | Centrifugal pipeline pump | 1 | set |

| Meter | Electromagnetic flowmeter, vortex flowmeter, pressure gauge, etc | 1 | suite |

| Valve | Electric ball valve, solenoid valve, safety valve and so on | 1 | suite |

| Navar | Control cabinet (Siemens PLC) and supporting cable and wire components | 1 | suite |

Process Principle

Process Flow Description

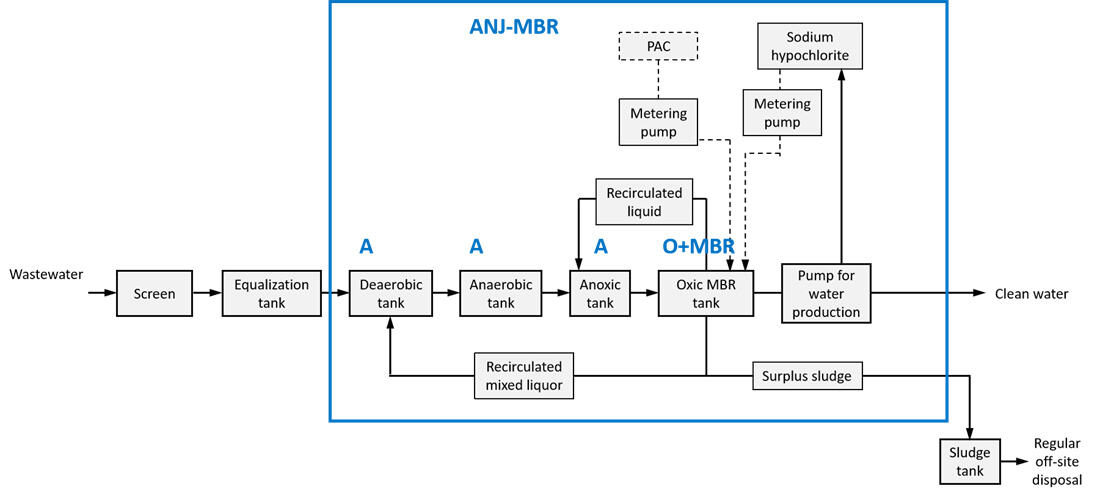

The wastewater first passes through screen to remove large particulate impurities, then enters the equalization tank to balance water quality and quantity. It subsequently flows into the deaerobic tank, where recirculated mixed liquor from the oxic MBR tank releases dissolved oxygen to maintain an anaerobic environment in the subsequent anaerobic tank. The water then enters the anaerobic tank where phosphorus-accumulating bacteria release phosphorus and consume organic matter.

It proceeds to the anoxic tank, where denitrifying bacteria utilize organic matter and nitrate nitrogen from recirculated liquid for denitrification. Finally, it enters the oxic MBR tank where microorganisms degrade organic matter and nitrify ammonia nitrogen. Excessive phosphorus uptake by phosphorus-accumulating bacteria occurs during this process. The oxic tank mixed liquor achieves efficient sludge-water separation through MBR membrane modules, retaining activated sludge and impurities while allowing clean water to pass through the membrane system for compliant discharge.

Technical Principles

This wastewater treatment system integrates advanced membrane separation technology with conventional activated sludge processes. Compared to traditional methods, it features innovative optimizations in critical aspects like process design and membrane fouling control, ultimately forming a comprehensive integrated system combining deoxidize, anaerobic digestion, anoxic conditions, and oxic processes (MBR membrane tank).

The membrane modules in the MBR process utilize flat-sheet membranes with a pore size of 0.1 μm. When activated sludge mixed liquor from wastewater flows through the membrane surface in the membrane tank, water and small molecules pass through the membrane pores to become treated effluent. Meanwhile, activated sludge, large organic molecules, bacteria, and other substances are retained by the membrane, remaining within the tank. This mechanism achieves effective solid-liquid separation.

Due to the high efficiency of the membrane, the activated sludge will not be lost with the effluent, and the high sludge concentration can be maintained in the bioreactor. The high sludge concentration means that more microorganisms are involved in the degradation of pollutants, which improves the biological treatment efficiency and enhances the adaptability of the system to the changes of water quality and quantity.

The A-AAO process utilizes different microorganisms under varying environmental conditions to remove nitrogen, phosphorus, and organic matter from wastewater. The MBR process enhances solid-liquid separation efficiency and biological treatment effectiveness through membrane separation technology. The integrated A-AAO+MBR wastewater treatment system combines these two approaches, effectively removing various pollutants from sewage while ensuring effluent quality meets stringent standards.

Product Core Technology and Characteristics

Core Technologies

Efficient and synergistic composite biological treatment process

(1) Synchronous and efficient nitrogen and phosphorus removal: Through the creation of alternating anaerobic, anoxic and oxic environments, phosphorus polypiling bacteria (PAOs) and nitrification/denitrification bacteria are cultivated respectively to achieve efficient and synergistic removal of total nitrogen (TN) and total phosphorus (TP) in sewage.

(2) Strengthening organic matter degradation: multi-stage reaction makes organic matter be degraded by different kinds of microorganisms step by step, so the treatment is more thorough and the load impact is strong.

Plate film technology for solid-liquid separation

(1) Nearly absolute solid-liquid separation: can 100% retain activated sludge, bacterial flocs and macromolecular organic matter, ensure clear and transparent effluent, and very low suspended solids (SS).

(2) High flux and stability: Compared with other forms of membranes (such as hollow fiber membranes), the selected flat membrane has the characteristics of strong anti-pollution, good cleaning recovery and more stable operation.

(3) Ensure the quality of effluent: Membrane separation is a physical barrier, which can effectively remove bacteria and most viruses, so that the quality of effluent can be stable to meet or better than the high standard reuse requirements.

Deep coupling and innovative optimization of process and membrane technology

(1) Maintaining ultra-high sludge concentration: The retention effect of the membrane can maintain a much higher sludge concentration (MLSS) in the bioreactor than that of traditional processes, thus greatly improving the treatment efficiency and shock load capacity per unit tank capacity.

(2) Simplify the process and save the area: the integrated design saves the secondary sedimentation tank, filtration and other subsequent units, and the system structure is compact and the area is small.

(3) Intelligent membrane pollution control: Through unique process design and operation strategies (such as optimized aeration, low-frequency cleaning, etc.), membrane pollution can be effectively reduced, membrane life can be extended, and operation energy consumption and cleaning frequency can be reduced.

Product Features

(1) Excellent effluent quality: can effectively remove all kinds of pollutants, can meet the environment sensitive and small capacity scenarios, and the effluent quality is stable.

(2) Small footprint: The integrated design and compact structure integrate biological treatment and membrane separation into one equipment, without secondary sedimentation tank, sludge concentration can be up to 8000-20000mg/L, the treatment efficiency is far higher than the traditional sewage treatment technology, and the footprint is saved by more than 2/5.

(3) High degree of automation: PLC remote control and automatic operation can be realized, and the equipment can be unattended. The operating condition and water quality of the equipment can be monitored in real time, and the operation management is simple.

(4) Intelligent operation: Through the automatic control system, the automatic cleaning control of the membrane can be realized, and the operation and maintenance are simple.

(5) Less sludge yield: the sludge age is long, and the amount of surplus sludge is relatively small, which reduces by 30%-50% compared with traditional sewage treatment processes, reducing the cost of sludge treatment and disposal and the risk of secondary pollution.

(6) Long membrane pollution cycle: The speed of membrane pollution is greatly reduced by optimizing the equipment design, and the membrane pollution cycle is extended. Meanwhile, the cleaning cycle and frequency are automatically controlled, which significantly reduces the operation and maintenance costs.

(7) Strong impact load: the biological treatment unit can maintain a high concentration of activated sludge, MLSS can reach 8000-20000mg/L, can tolerate large fluctuations in water quality and water quantity, and can maintain stable treatment effect under the condition of large changes in sewage quality and water quantity.

(8) Strong adaptability: it can be customized according to different sewage quality and treatment requirements, and is suitable for urban sewage treatment plant (station) upgrading, tourist attractions, expressway service areas, rural sewage treatment scenarios, and can also be used for pretreatment or independent treatment of small and medium-sized industrial wastewater.

(9) Standardization and Customization Services: We pursue excellence in intelligent manufacturing through digital transformation and automation upgrades. By actively expanding the application of big data analytics and artificial intelligence technologies, we dedicate ourselves to smart manufacturing to deliver outstanding products and services. Our offerings include not only a range of rigorously tested, high-performance standardized products tailored to diverse industry needs, but also customized solutions developed by our professional design team to meet unique requirements. Through comprehensive services, we craft premium mechanical products and system solutions with meticulous craftsmanship.

Differentiation Characteristics And Market Competitive Advantages

Compared with similar products, this product has good sewage treatment efficiency, especially in terms of operation and maintenance cost and intelligent control.

Table 5-1 Comparison of similar products

| Contrast project | ANJ-MBR | Hirota, JapanIntegrated sewage treatment equipment | Memstar integrated sewage treatment equipment | Bishuiyuan intelligent MBR sewage treatment equipment |

| Main technology | Activated sludge method + biofilm method | Activated sludge method + biofilm method | Activated sludge method + biofilm method | Activated sludge method + biofilm method |

| Type of membrane | Flat sheet membrane | Flat sheet membrane | Hollow fiber membrane | Hollow fiber membrane |

| COD removal rate | 80%-90% | 80%-90% | 82%-90% | 85%-90% |

| Ammonia nitrogen removal rate | 75%-90% | >85% | 80%-90% | 80%-88% |

| Dephosphorization productiveness | 80%-95% | 80%-90% | 80%-85% | 80%-90% |

| Sludge concentration | 8000-20000mg/L | 8000-15000mg/L | 8000-12000mg/L | 6000-12000mg/L |

| Membrane life | 5-8 years | 5-8 years | 3-5 years | Domestic sewage: ≥5 years; industrial wastewater: 3-5 years |

| Cleaning frequency | Intelligent monitoring self-cleaning | Physical backwash: daily; chemical cleaning: every 3-6 months | Physical backwash: daily; chemical cleaning: once a month | Online chemical cleaning: once a week |

| Level of intelligence | Integrate AI algorithm + smart Internet of ThingsIntelligent operation and maintenance management platform | Basic PLC control | Central control + Internet of things remote monitoring | Integrate AI algorithm and digital twin operation and maintenance platform |

| Apply scene | Municipal sewage, rural decentralized treatment, emergency scenarios, small and medium-sized industrial wastewater | Large municipal sewage plants, industrial parks | Dispersed sewage, industrial wastewater | Municipal sewage, rural decentralized treatment, emergency scenarios |

Applications

Rural Sewage Treatment in Hefei City, Anhui Province, China

Project Background and Challenges:

• Project location: a rural area in Anhui Province, China.

• Processing scale: 50m³/d.

• Main challenges: The project is close to the first-level protection area of Chaohu Lake, with limited land and strict requirements for water discharge.

ANJ-MBR Solution:

• One MBR-50 model combination is adopted.

• The MBR process eliminates the secondary sedimentation tank, filtration and other subsequent units, and the system structure is compact and the footprint is small.

• The A-AAO+MBR process has the advantages of high simultaneous nitrification and denitrification, high nitrogen and phosphorus removal efficiency, high sludge concentration, strong anti-impact load capacity, high SS retention rate and clear effluent.

• Equipped with intelligent operation and maintenance platform, remote monitoring and intelligent low-frequency cleaning can be realized, which simplifies operation and maintenance and reduces energy consumption.

Implementation effect and data:

• The effluent water quality is stable to meet the local standard, in which the effluent COD is less than 30mg/L, far better than the local standard.

• The area occupied has decreased by approximately 40%.

• Operation and maintenance costs reduced by about 30%.

Please provide your project data so that we can design a more suitable equipment for you.

| Parameter | Inflow water quality (mg/L) (ppm) | Water quality (mg/L) (ppm) |

| CODCr | ||

| BOD5 | ||

| TSS | ||

| NH4+-N | ||

| TN | ||

| TP | ||

| pH | ||

| Colibacillus | ||

| Other | ||

| Handling capacity | m3/d | |

| Whether to assemble in the control room | ||

| Appearance requirements | For details of the minimalist look, please refer to our brochure. | |

| Voltage, frequency, electrical phase | ||

| Distance between regulator and equipment | ||

| Flange interface specifications | ||

| Special requirements | ||